This week we have not one but twelve cars. They are Front Range Products ACF 3 bay Grain Cars. Front Range Products were around in the late 80’s and early 90’s. Their demise is something of scandal, but their products had some of the nicest detail at the time.

A side note. Most of the Front Range cars that I have are “inherited”. I was working with a guy back in the early 90’s who was “in search of a hobby”. After talking to me and another coworker about model railroading he thought it might be for him. Doing some research he decided on the Duluth, Missabe & Iron Range. He bought a bunch of engines and cars. I helped him finish off some space in his basement for a small layout and work bench.

One day he walks up to me and tells me he’s getting out of the hobby. It’s just not for him. He was able to return some of the stuff to the LHS. Sold some of it off. And he gave me a bunch for helping him out. Thus, “inherited”.

Anyways, I pulled one of the boxes out from the “to be built” shelf. It was a Southern grain car. No Instructions in the box. Although the only thing I really needed to know was the correct placement of the triple valve and the brake actuator. Remembering that I had seen some more FRP cars down in the “completed” section (I keep the cars grouped pretty much by manufacturer) I went and looked. Turns out there were a dozen cars there. Going through the boxes I found that they were in various stages of disarray. A couple were not assembled, some were OK and others had various things broken off.

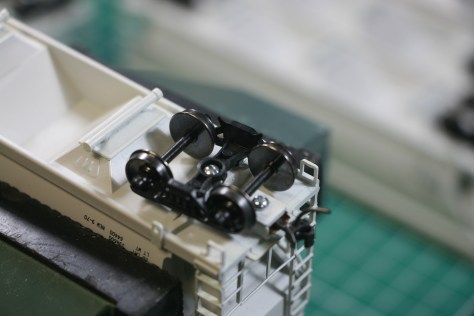

And so the construction and repair began. FRP used pins to hold the trucks on. My friend used super glue to hold the friction pins in place. Most were either too tight or not tight enough. He also used super glue to secure the draft gear boxes. Some of the couplers were glued in place. I assembled the cars that weren’t put together, the one Southern car, a Chicago & Northwestern car and a CanCarb car. On these I tapped out the truck mounting hole and used 2-56 screws to hold them in place. The draft gear boxes I went with the friction fit covers and if they were a bit loose I used canopy glue on them. Canopy glue is great, it’s tacky and sets fast, dries clear and you can remove the part without damage if you need to.

The rest were handled on a case by case basis. All had the truck pins removed (ie. broken off) and then I drilled and tapped the hole and mounted the trucks with screws. The couplers that were free moving I left alone at this time. The ones that were frozen (glued) in place or didn’t move freely were handled like the trucks. I broke the cover off and then drilled and tapped for a screw.

As it turned out, the Southern car was one of a six car set. Each had it’s own separate reporting number. There was one car I tossed. The weights inside had come loose and he had glued the car together. So no fixing it. It was also missing a bunch of parts. So rather than having it sit around, away it went.

And I present to you the cars…

And that’s not all…

Rather than a separate post, I’ll just include them here. I came across another bunch of center beams. It’s a three car set from Walthers. Same as the others, I added a load and secured it using thread to simulate cabling holding the load in place. Because the cars were a lighter paint color, I painted the spool of the ratchet black so that it looks like more cabling is wrapped around it. The single thread stood out as just that, a single thread stuck to the side of the spool. It looks pretty good painted.

Have a great weekend, I’ll see you next week. Till then…